Electrical 2D/3D

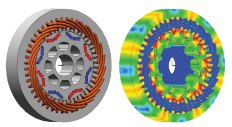

Uses the finite element method to solve for the electric field strength, forces, capacitances and other quantities. Electrical can simulate static, AC and transient electric field and current flow problems.

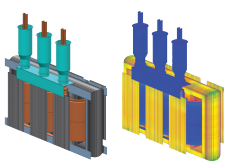

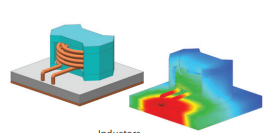

Thermal 2D/3D

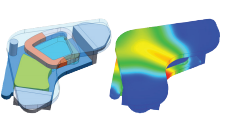

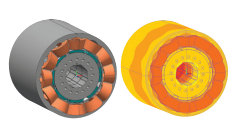

Geometry, materials and mesh details are all seamlessly exchanged between Simcenter™ MAGNET™ for electromagnetic or electric fields. Coupling allows the materials to be updated based on local temperature distributions within each component. Solve for either the steady state or the time-varying temperature distributions caused by the conductor and magnetic losses. Various forced convection fluid cooling options can be added to the simulation to assess performance.