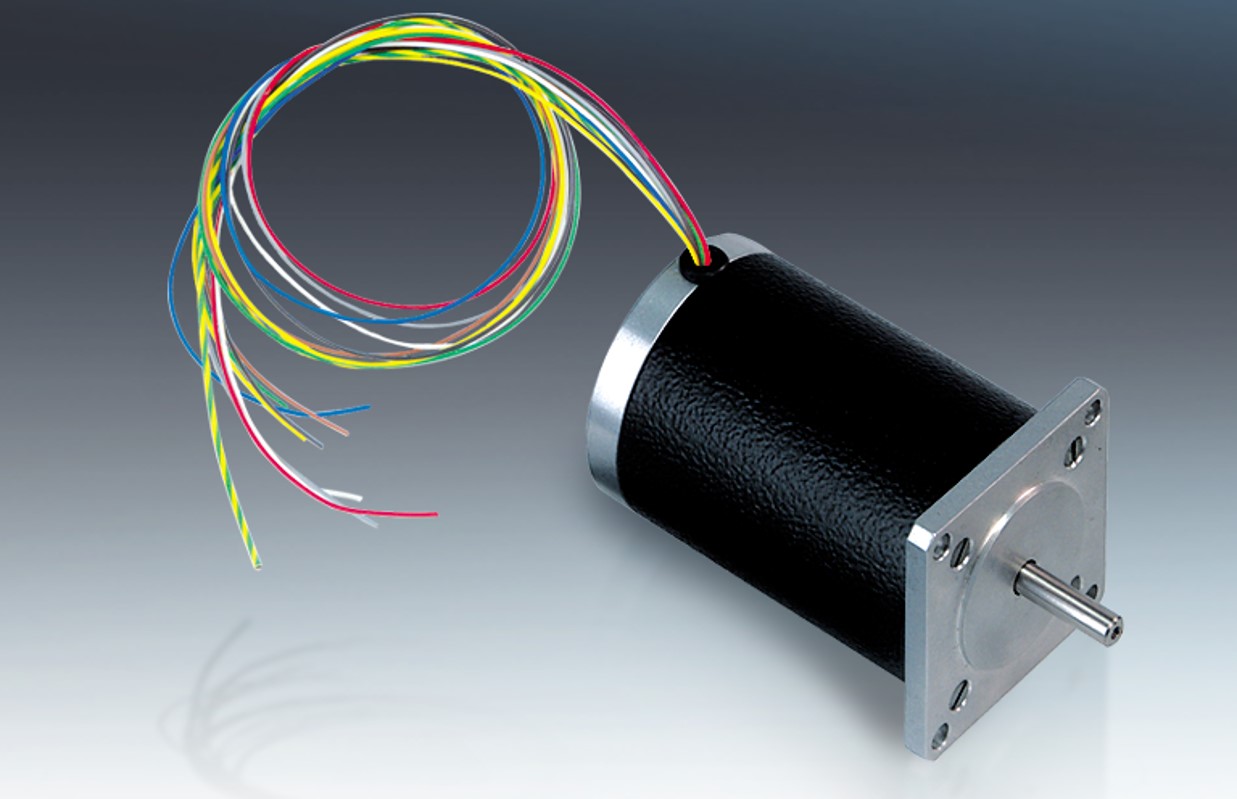

Our stepper motors are hybrid motors equipped with axial rare-earth magnets, generating high torque. Hybrid motors combine the advantages of permanent magnets and reluctance motors, resulting in optimal performance. The use of rare-earth magnets allows for a high magnetic field strength and thus high torque in a compact design.

Most of our stepper motors are two-phase motors with 50 pole pairs. In full-step mode, this translates to 200 full steps per revolution for two-phase motors. This enables precise movements and positioning.

By employing microstepping technology, the effective resolution of the stepper motors can be increased by up to a factor of 256. This means that even finer intermediate steps can be generated between the full steps, resulting in even more precise motor control.

Stepper motors are still widely used today and have their justified place in many applications. They are often chosen for cost reasons, as they provide a cost-effective solution compared to other types of motors. Additionally, they are suitable for applications where a standstill at the end of motion without additional control activities is desired. Stepper motors also exhibit a high torque density at low speeds, making them ideal for applications requiring high forces.

Thanks to modern control techniques, the running behavior of stepper motors has been significantly improved. In the past, "step loss" was a common issue where the motor could not hold its position due to exceeding the allowable torque. However, with the implementation of true servo operation in many controllers, this problem has largely been overcome. This allows for precise and reliable positioning tasks with stepper motors.

In addition to stepper motors, we also offer flexible stepper motor controllers in various configurations. Our Stepnet series provides a wide range of control options for precise driving and regulation of stepper motors. This enables customers to select the stepper motor that is best suited for their specific application, ensuring reliable and efficient control.

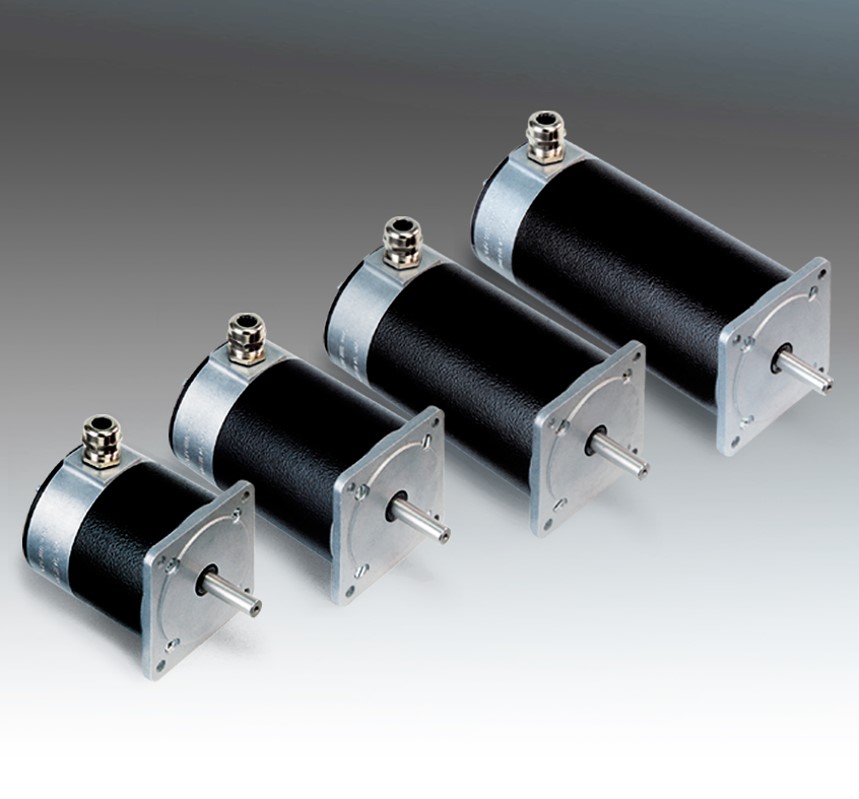

Our stepper motors, manufactured by the renowned STÖGRA, are 2-phase 1.8° hybrid stepper motors. They are known for their high quality and reliability. With a wide range of stepper motors available in different sizes and power ratings, we provide our customers the opportunity to choose the stepper motor that is optimal for their application. This way, they can ensure that their requirements for precision, torque, and size are met.