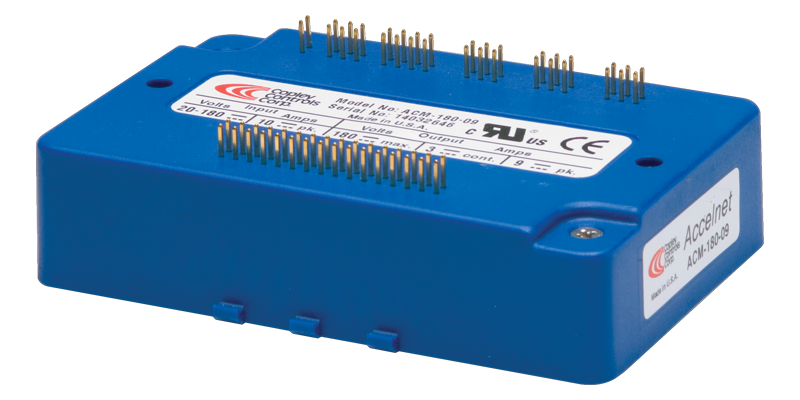

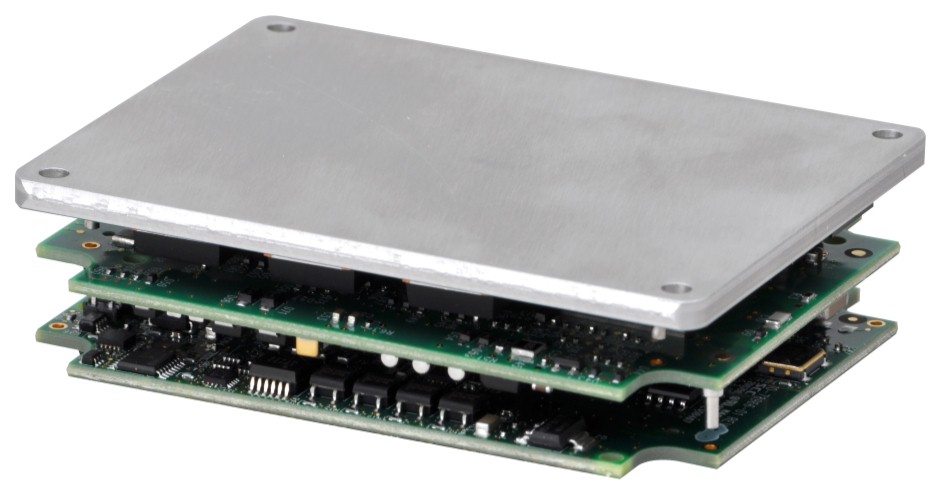

Our manufacturing partner, Copley Controls from the USA, is expanding its current FPGA-based BLDC controllers with "ARGUS" - a compact controller designed for low voltage (9-55Vdc and 14-90Vdc) and high continuous/peak currents (30/60A). This new product is targeted at mobile applications with low onboard voltages. There is also a rugged version available for harsh environments.

The ARGUS servo drive supports various encoder interfaces, including digital incremental encoder (RS-422) and analog encoder (sin/cos, 1Vss), EnDat, BiSS (B and C), SSI, and Absolute A (Panasonic, Tamagawa, and Sanyo Denki), as well as resolver and digital hall sensors.

The servo drive offers multiple programmable digital inputs and outputs. It allows high-speed position capture and position-triggered output setting. An analog +/-10V input with 12-bit resolution can be used as a command path for the ARGUS.

The ARGUS is built on Copley's proven FPGA structure, and for configuration and programming via the RS-232 interface, it utilizes the well-established and powerful commissioning software CME2, which is already used with other controllers from Copley. This enables easy handling of mixed applications with various Copley controllers. CME2, based on Java, comes with integrated tools like autotuning routine, oscilloscope, and other diagnostic tools, making commissioning a breeze.

The Copley ARGUS servo drive is specifically designed to deliver optimal performance for DC-powered applications with low voltage starting from 9Vdc and high motor currents. Due to these features, the ARGUS servo drive is particularly well-suited for battery-operated applications with 12V, 24V, or 48V onboard voltages, such as vehicles, automated guided vehicles (AGVs), or mobile medical devices.

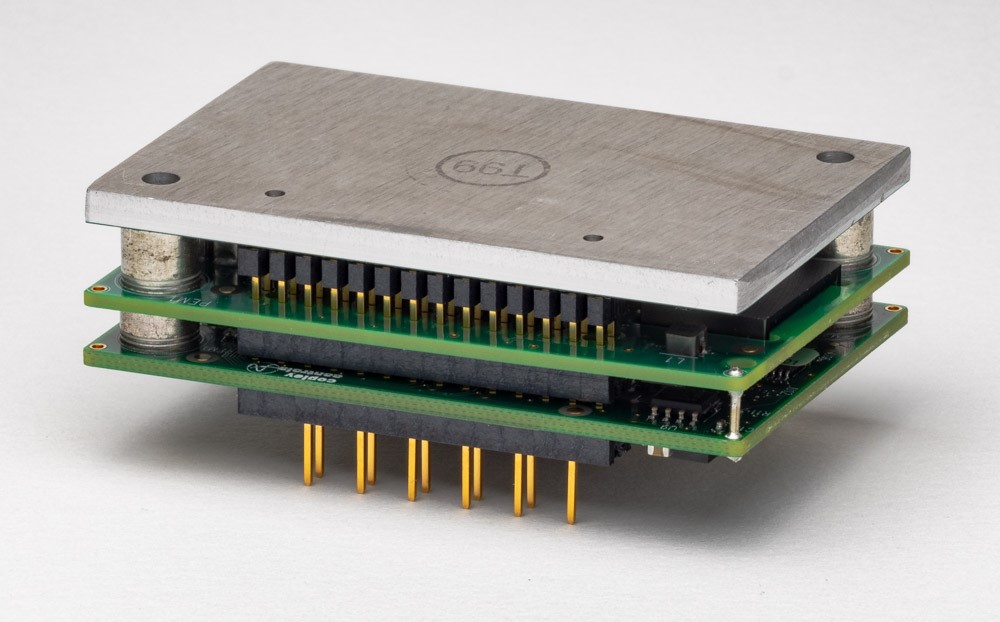

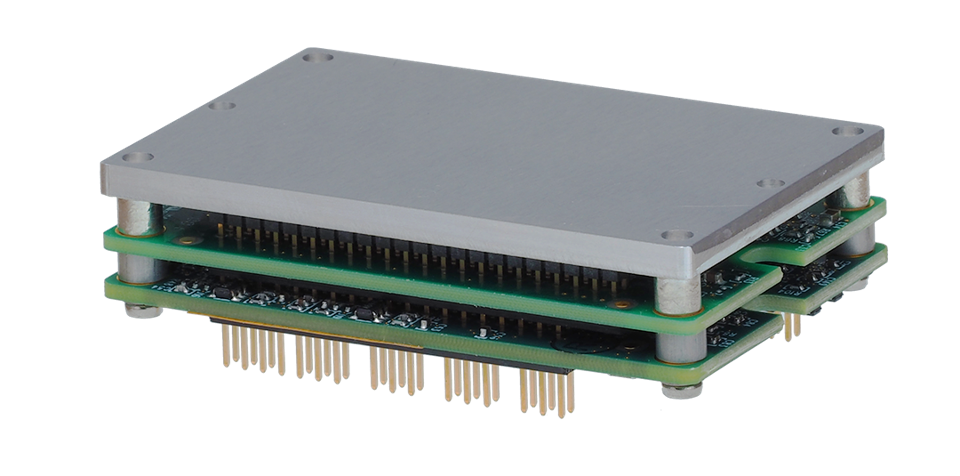

The GEM module/GPM module is an extremely compact solution for Automated Guided Vehicles (AGVs) and robotics. It operates with voltages ranging from 9-55VDC and 14-90VDC, providing a continuous current of 30A. The Safe Torque Off (STO) functionality reduces system costs for safety-critical applications. The GEM module allows EtherCAT control interface via the CoE protocol, while the GPM module offers CANopen communication as the control interface. Both the GEM module and GPM module are compatible with a variety of absolute encoders, including BISS, SSI, Absolute A, and EnDat.

The ARGUS servo drive offers the following key features:

- Operating modes: current, velocity, or position control

- Command input: EtherCAT, CANopen, RS-232, +/-10V, PWM, I/O (Indexer), Stepper, Master Encoder (Electronic Gearbox)

- Operating voltage: 9 Vdc to 55 Vdc or 14 Vdc to 90 Vdc

- Peak currents up to 60A

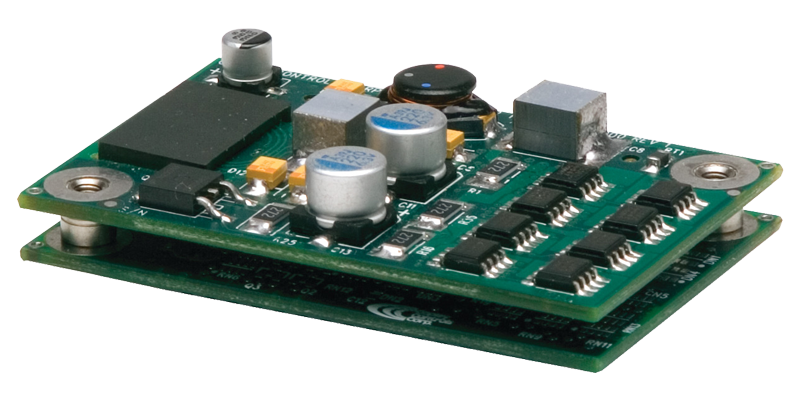

- Available as plug-in or solder-in module

- Excellent current resolution

- Numerous inputs and outputs

- Various feedback options, including absolute encoders: hall sensors, digital incremental encoder / sinusoidal encoder / resolver, absolute encoder (EnDat 2.2, BiSS, SSI, HD, Tamagawa, Panasonic, Sanyo Denki, Nikon)

- Support for fieldbus systems: CANopen, EtherCAT

- Safety features: Safe Torque Off (STO), SIL 3, Category 3, PL d