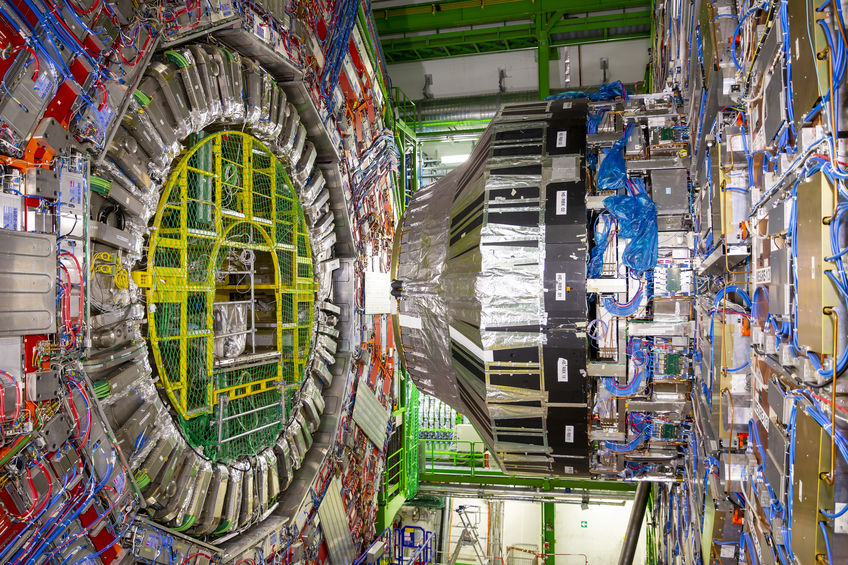

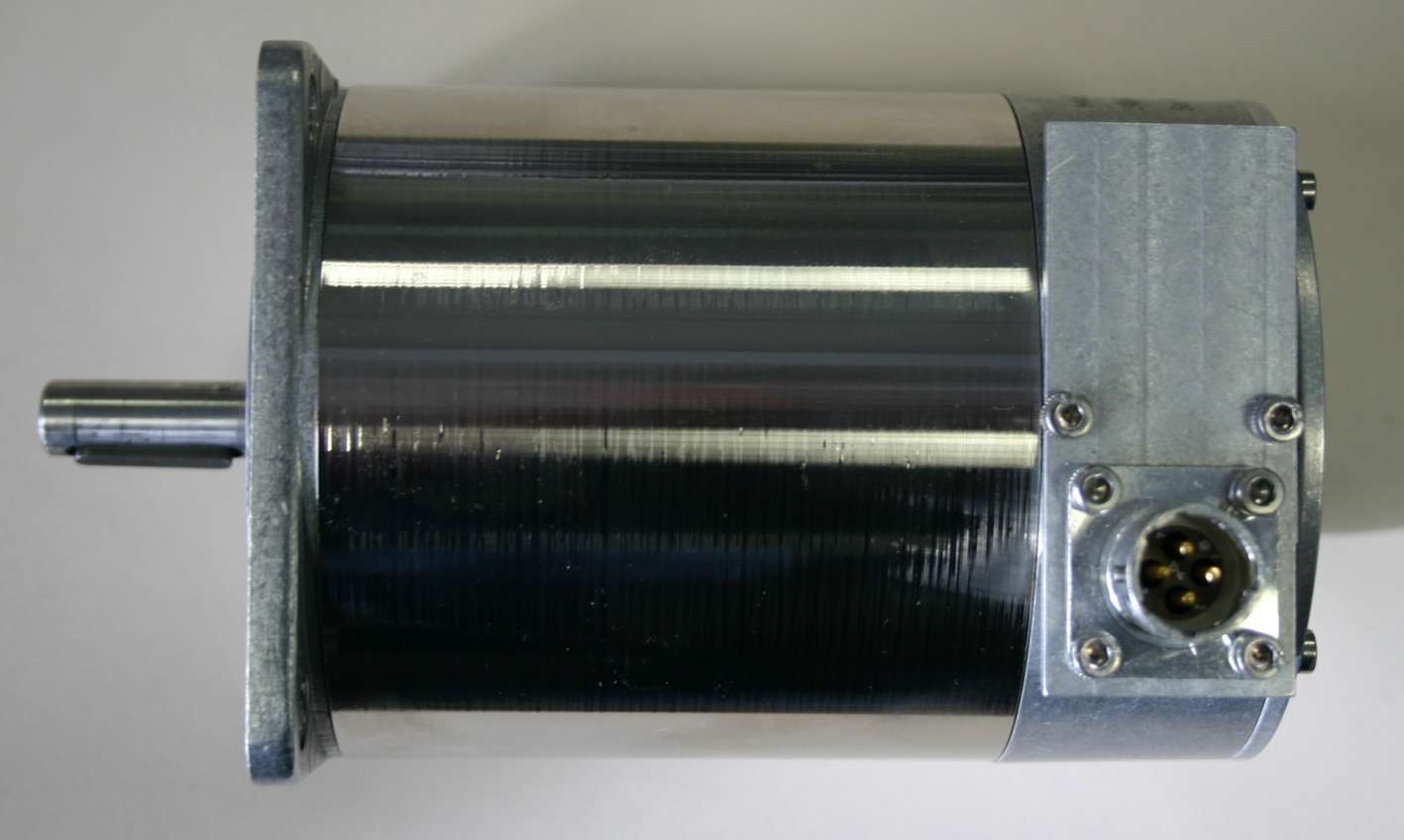

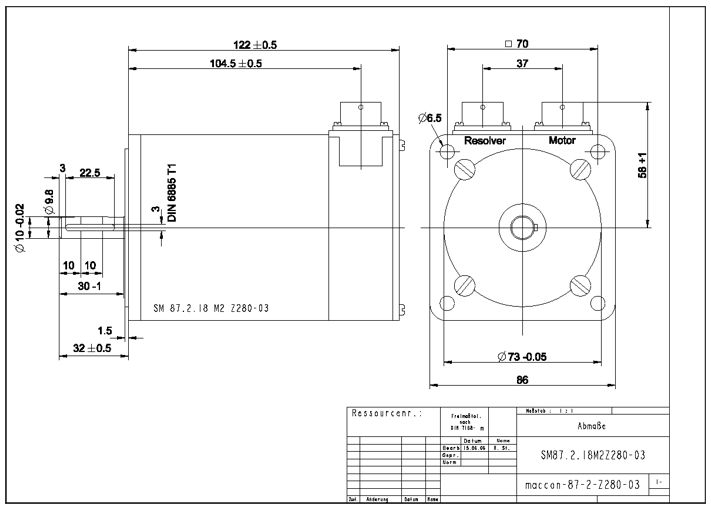

For certain scenarios in the fields nuclear power or scientific research, we are confronted with irriadated environments (environments subjected to high levels of radiation, especially gamma rays). This type of environment means it's impossible to use industrial-grade motors and rotor angle measurement systems, as they will disintegrate sooner or later, due to the effects of radiation on the non-metallic parts. For situations like this, MACCON has designed and built a radiation-hardended motor, based on stepper motor technology. The motor is available with or without a rotor angle measurement system (resolver feedback) and can therefore be operated in closed loop or open loop mode.

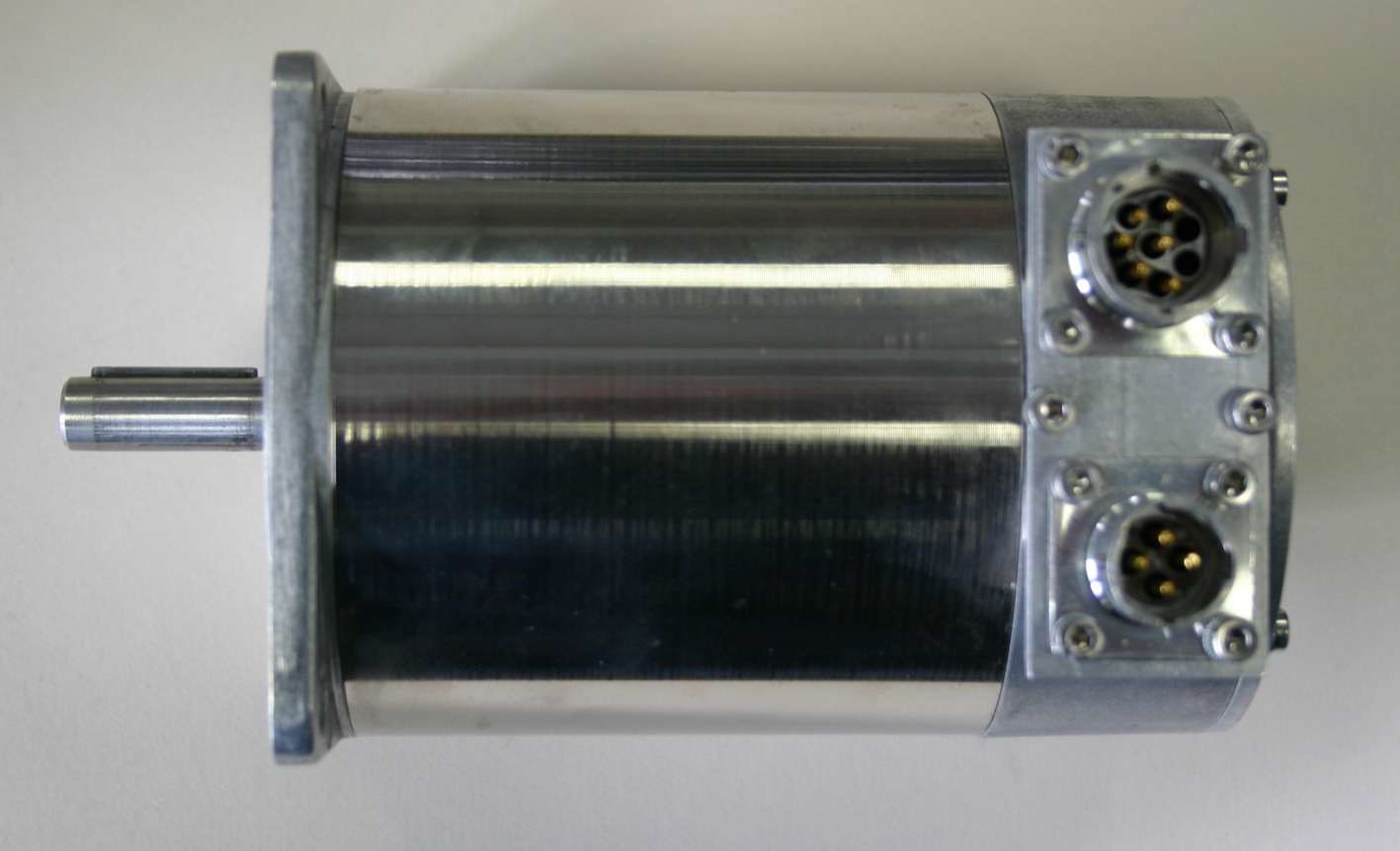

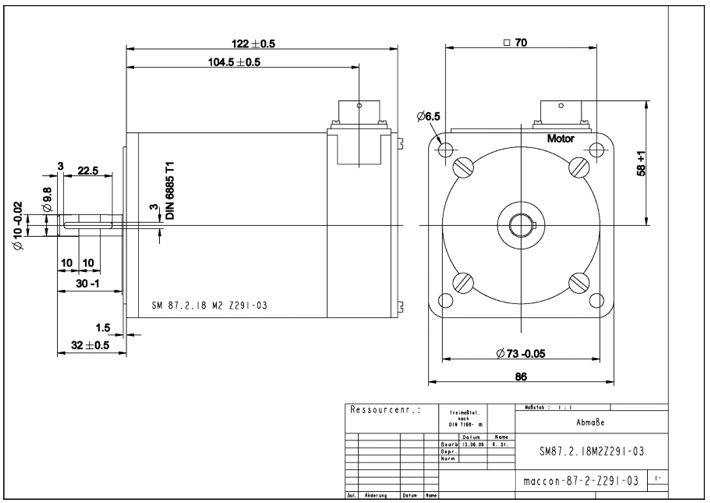

In the image on the right-hand side, the version with resolver feedback can clearly be seen (additional connector for feedback cable).