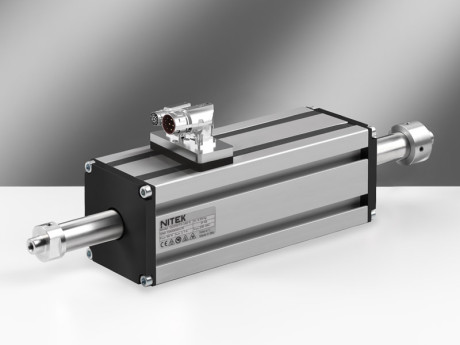

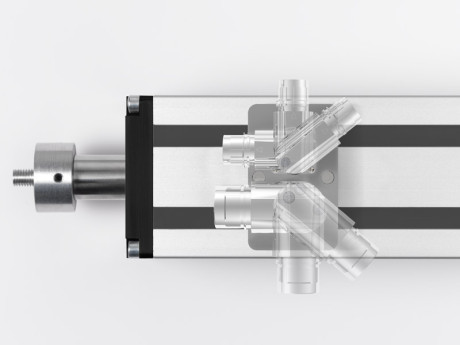

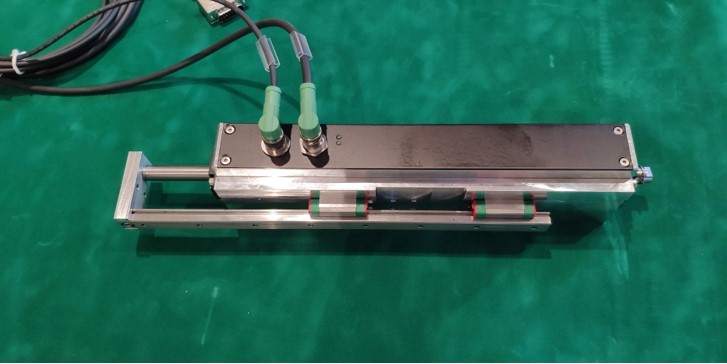

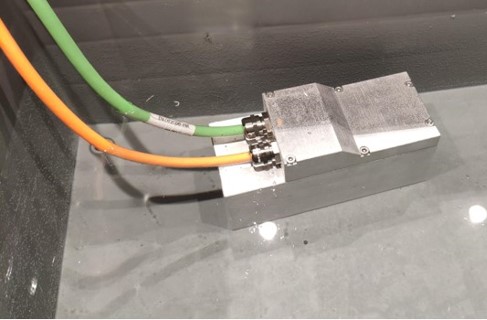

A tubular motor, also known as a tube motor or tubular linear motor, consists of a magnetic rotor and an electric coil in a housing. You can see this quite well in the picture on the right. The piston rod is the magnetic rotor (magnets placed at fixed distances in a tube). The box is the electric coil. The magnetic rotor slides through a plastic slide bushing, which is housed in the coil box. When the coil is energized, the magnetic rotor thus moves. An integrated distance measuring system enables position detection

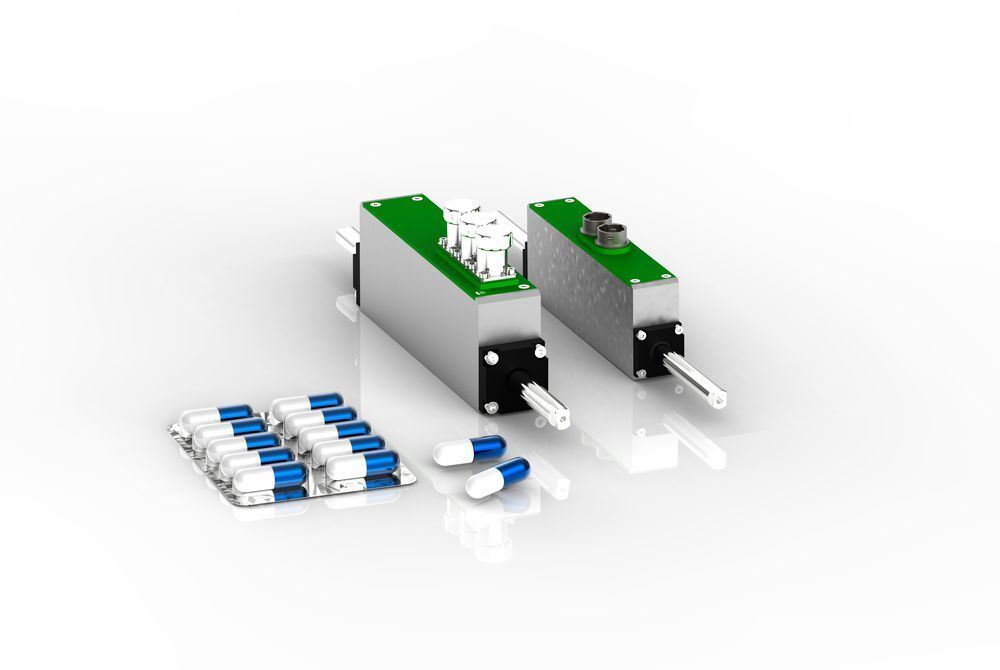

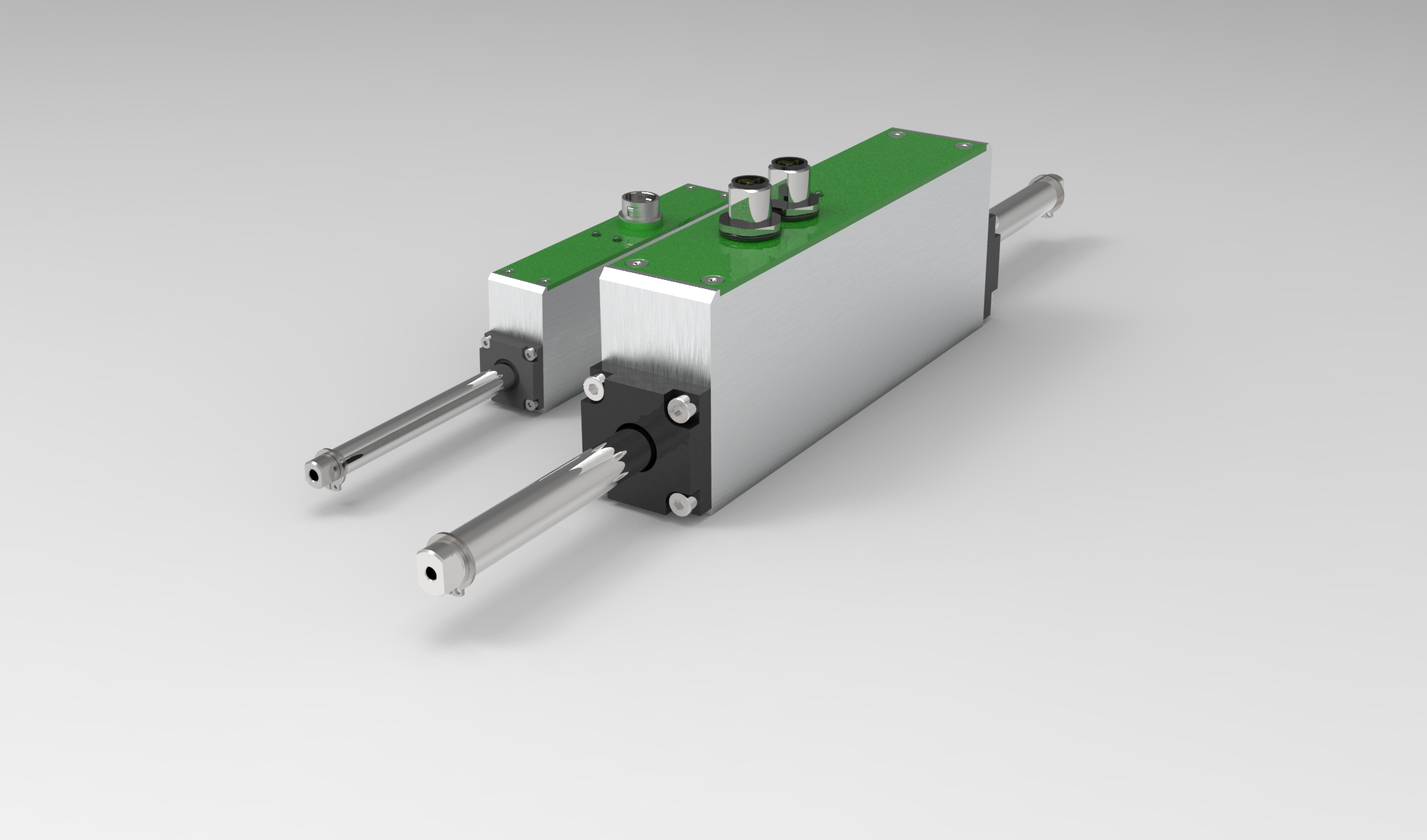

In the tubular motor category, we offer two distinct product families:

- Green Drive: For large forces and for 230Vac or 400Vac

- NL Series: For smaller forces and for 24Vdc or 48Vdc

In the following, you can find more detailed information about both families.