Industry

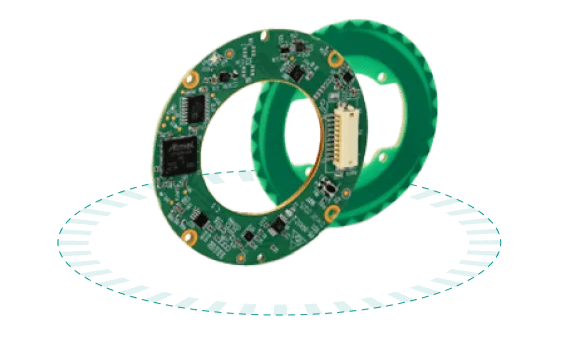

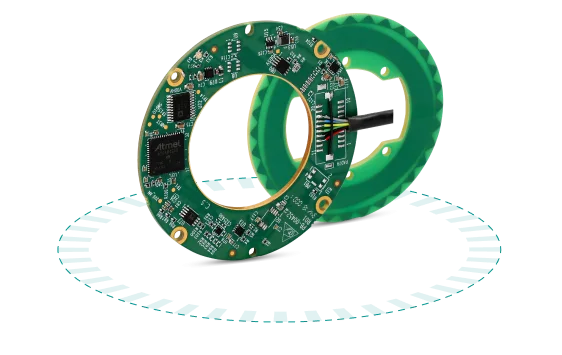

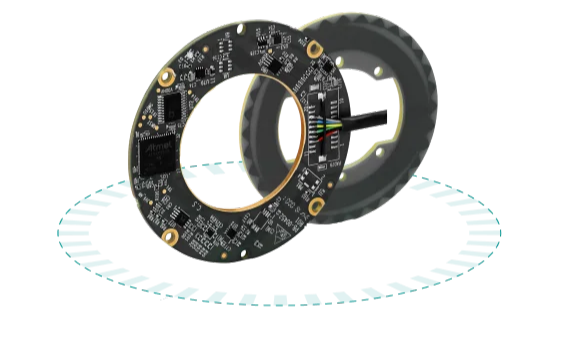

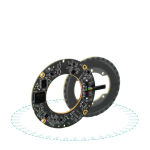

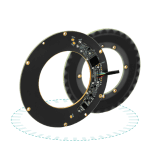

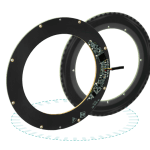

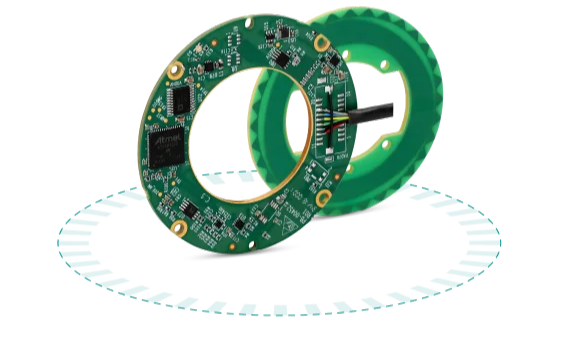

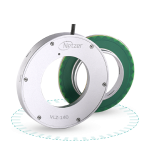

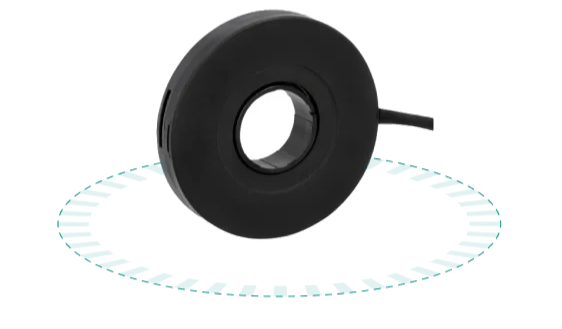

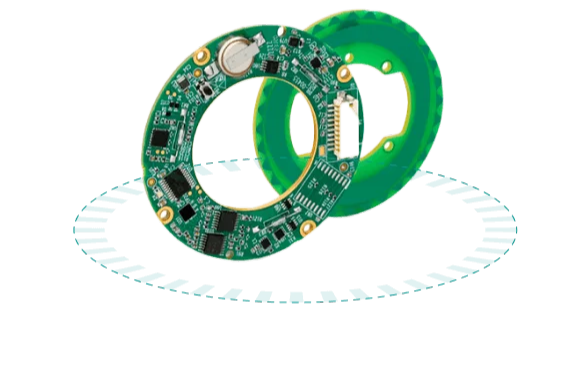

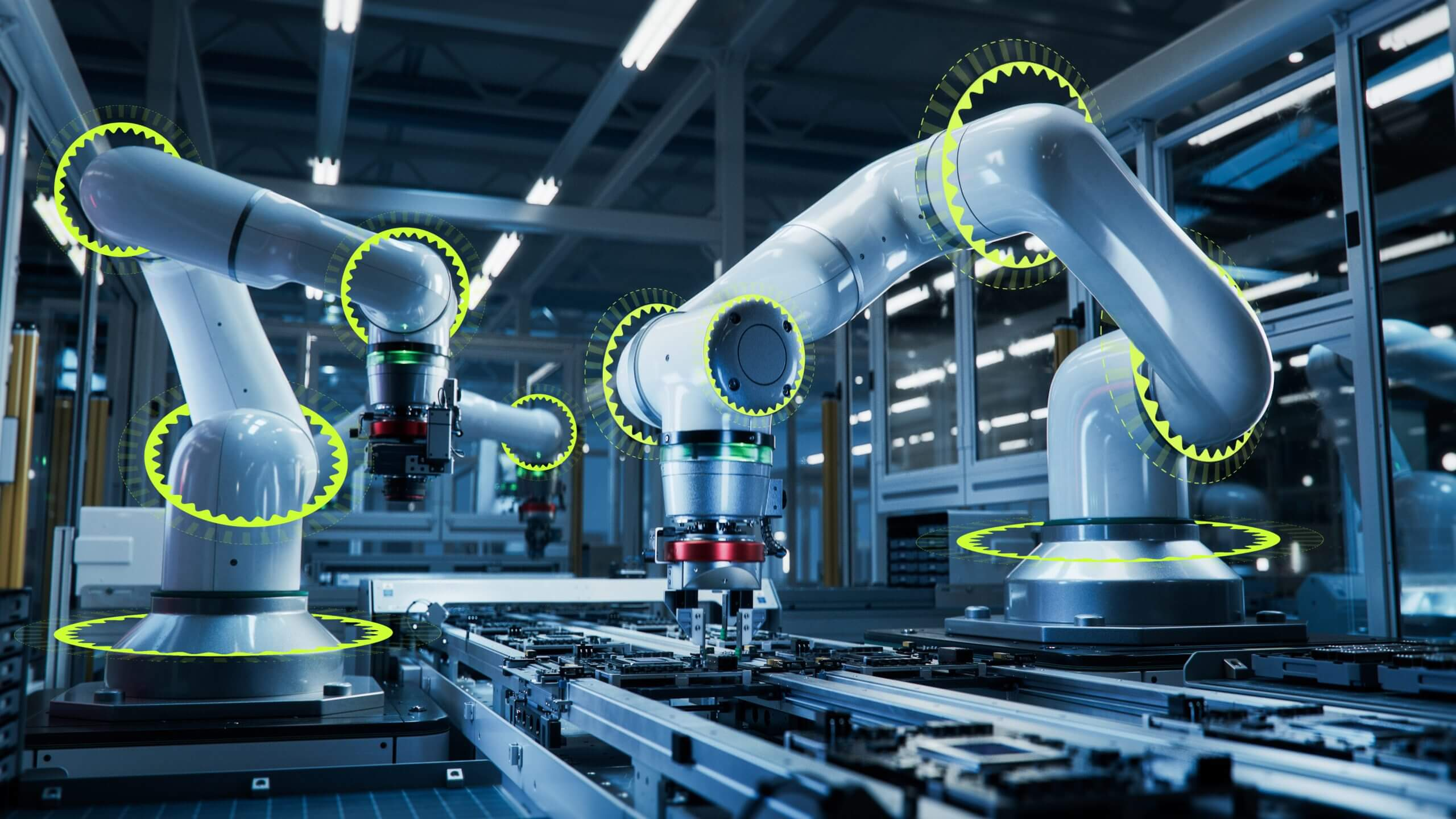

Compact and precise position sensors are required for applications in automated manufacturing, assembly, inspection, and material handling. The VL and DS series are particularly well suited for use in dynamic, motion-intensive environments thanks to their contactless design, high resolution, and low profile.

Typical applications:

Pick-and-place robots

Autonomous mobile robots (AMRs)

Axis control in handling and production systems

The encoders deliver absolute position values, operate virtually wear-free, and are resistant to dust and other environmental influences. Sizes starting from 13 mm outer diameter allow for integration even in space-constrained installations. Generous mechanical tolerances simplify mounting.

The encoders are ideal for use in factory automation, semiconductor production, and precision machinery.

Medical Technology

In surgical assistance systems and micro-surgical applications, precise and reliable position feedback is essential. VL and DS encoders are suitable for use in medical devices where even the smallest deviations must be avoided.

Typical applications:

Robot-assisted surgical systems

Micro instruments in surgery

Image-guided navigation and positioning systems

The encoders operate contactlessly and wear-free, deliver interference-free absolute values, and feature a flat, integrable design. The product series meets ISO 13485 requirements and is designed for reliable operation in sensitive systems.

Aerospace & Space

Compact, lightweight, and radiation-resistant position sensors are required for satellite and space projects in Low Earth Orbit (LEO). The VLS series offers contactless absolute encoders that have already proven themselves in several space missions.

Key features:

Flat design with hollow shaft

Low weight, from approx. 13 mm outer diameter

Radiation resistance (TID) and low outgassing according to space specifications

Series availability as a COTS component

The encoders are suitable for:

Attitude control in satellites

Actuators in mechanisms requiring high positioning accuracy

Systems with limited space and high reliability requirements

Harsh Environment

Robust, reliable position sensors are required for applications in extreme environmental conditions. VL and DS encoders are designed for use in environments with heavy vibrations, shock loads, temperature fluctuations, and electromagnetic interference.

Typical applications:

Flight control, gimbal systems, radar stabilization

Turret systems, unmanned ground vehicles, weapon platforms

Naval applications, missile guidance, underwater technology

The encoders operate contactlessly and wear-free, deliver absolute values, and can be integrated in a space-saving manner due to their flat design. Available sizes from 13 mm outer diameter allow for adaptation to various mechanical requirements.

Energy

In wind and photovoltaic systems, precise position sensors are required to reliably track components such as rotor blades or solar panels. VL and DS encoders are suitable for use in outdoor environments with changing weather conditions.

Typical applications:

Pitch control in wind turbines

Azimuth and elevation tracking in solar tracking systems

Yaw control and similar drive solutions

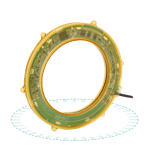

The encoders are available in various sizes from 13 mm to 247 mm. They operate contactlessly and wear-free, are resistant to dust, moisture, vibration, and temperature changes, and provide high-resolution absolute values.

Agriculture

Automated agricultural systems such as autonomous tractors, harvesting machines, or seeding technology require precise and robust position sensors. The contactless absolute encoders of the VL and DS series are particularly suitable for outdoor use thanks to their flat design, high resolution, and resistance to dust, vibrations, and weather influences.

With sizes starting from 13 mm, they offer reliable position feedback even in space-constrained applications — e.g. for steering, robotic arms, or navigation. The encoders are low-maintenance and designed for continuous operation in harsh conditions.