Space-rated wound and reluctance resolvers

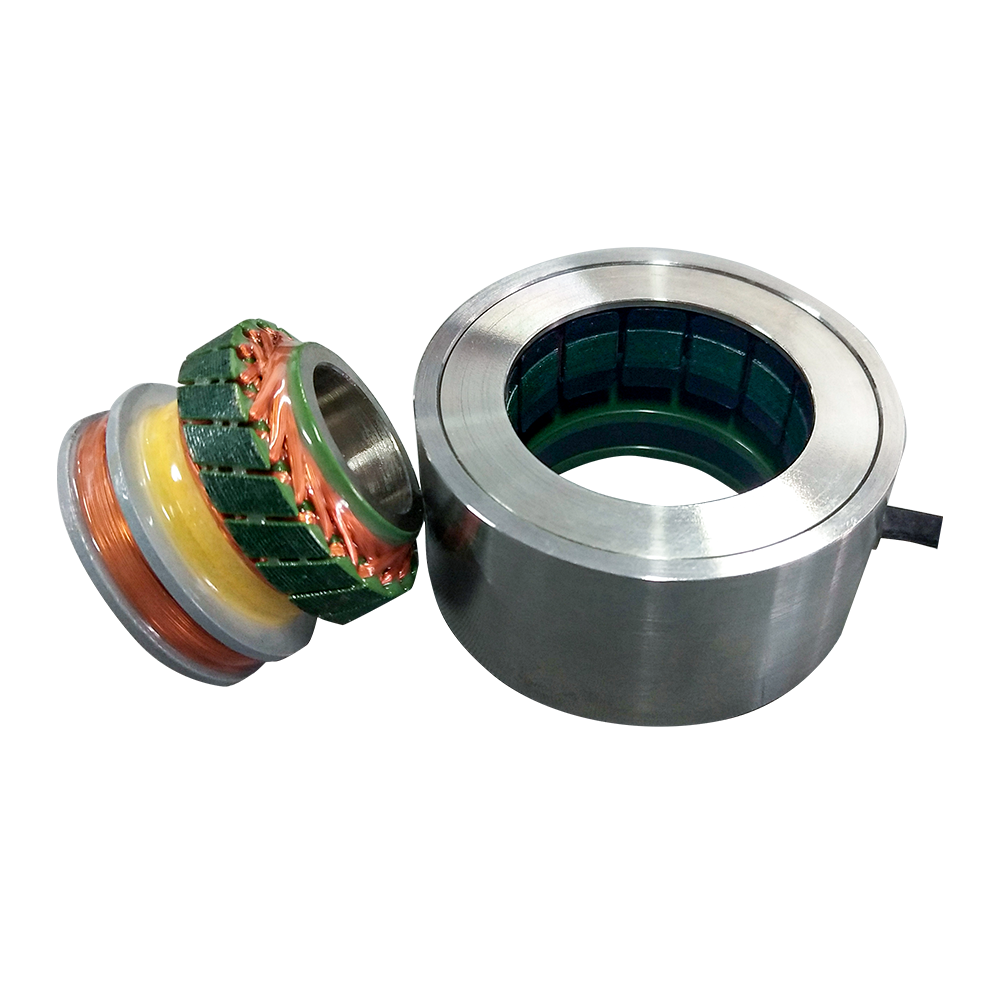

We also offer the well-known wound resolver as a space-rated variant (see picture on the right). Less well known, however, is the reluctance resolver, which has certain advantages and disadvantages over the wound resolver. See table further below for a comparison of the two technologies.

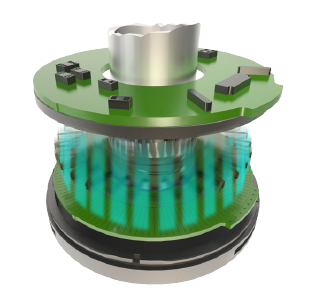

The variable reluctance resolver (VRR) consists of a rotor and stator (see picture on the right). The stator consists of insulated copper wire windings (primary and secondary) wound on laminated silicon steel. The rotor is oval-shaped and consists only of laminated silicon steel. The oval shape of the resolver causes a change in reluctance when the rotor revolves inside the stator. This change in reluctance can be used to detect the rotor angle. In contrast to conventional resolvers (rotor and stator both wound), reluctance resolvers have both primary and secondary windings on the stator and do not need a winding in the rotor. This offers many advantages in terms of cost, mass and space requirements. The variable reluctance resolver weighs less, has a shorter axial length and costs less than a conventional resolver.

We manufacture our reluctance resolvers in-house using ESA-certified materials (e.g. a low outgassing potting compound for the stator winding, nickel-plating of stator/rotor lamination stack). We can also offer a redundant stator winding if required. We offer resolvers with different inner and outer diameters.