Torque motor for harsh environments

The STK family of kit torque motors also offers variants for harsh environments. There are three different possible ways to harden the motor against harsh environments.

The standard torque motor uses a rotor with glue-bonded magnets, suitable for lowerspeeds in direct drive mode in a dry industrial environment. For environments with excessive moisture, aggressive chemicals and increased mechanical stress on the motor, a motor with suitable hardening is required. Also, if the customer wants to run the motor at speeds higher than the rated speed, a special protection is required against centrifugal forces.

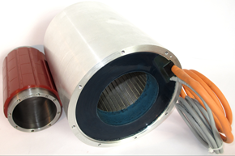

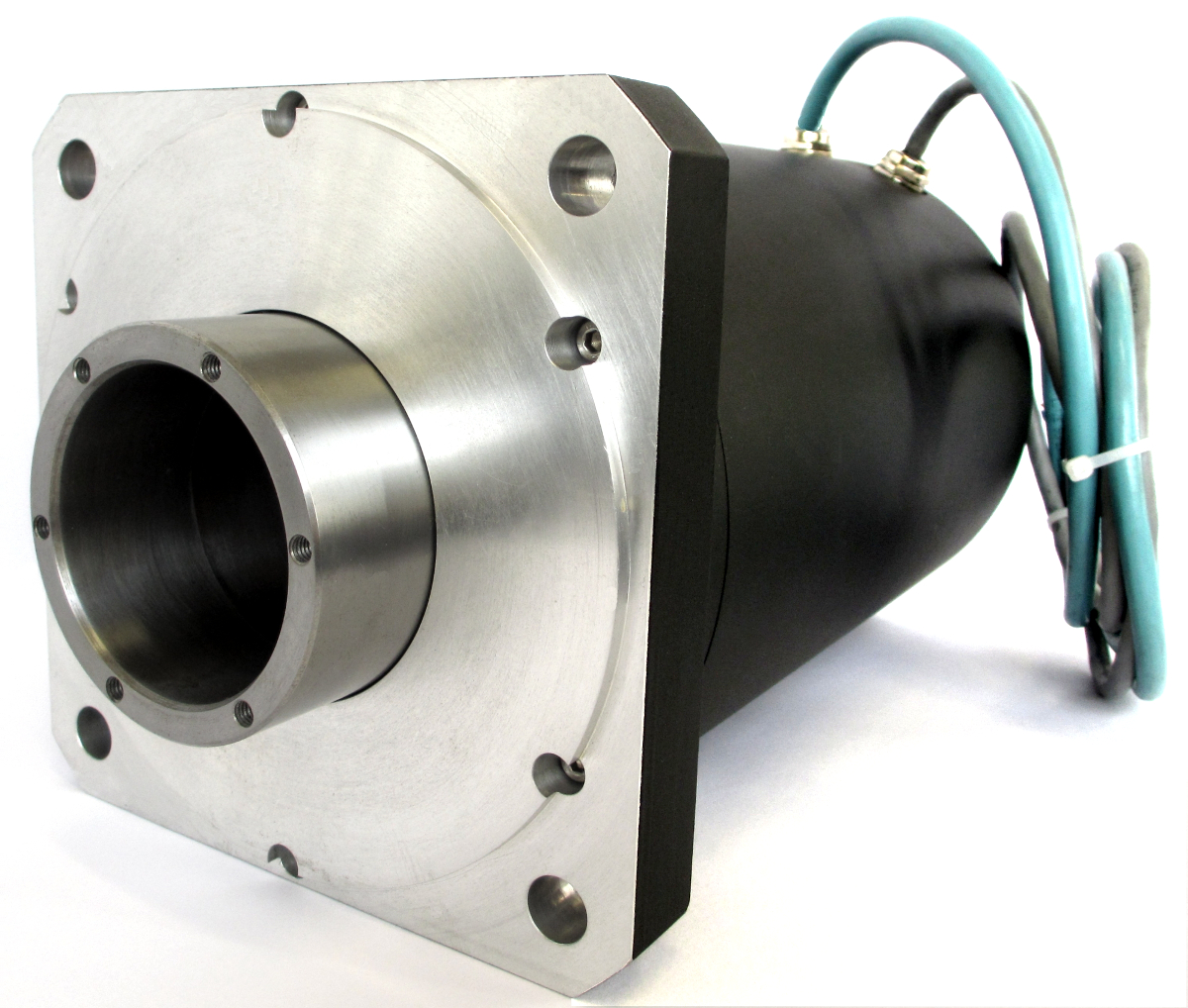

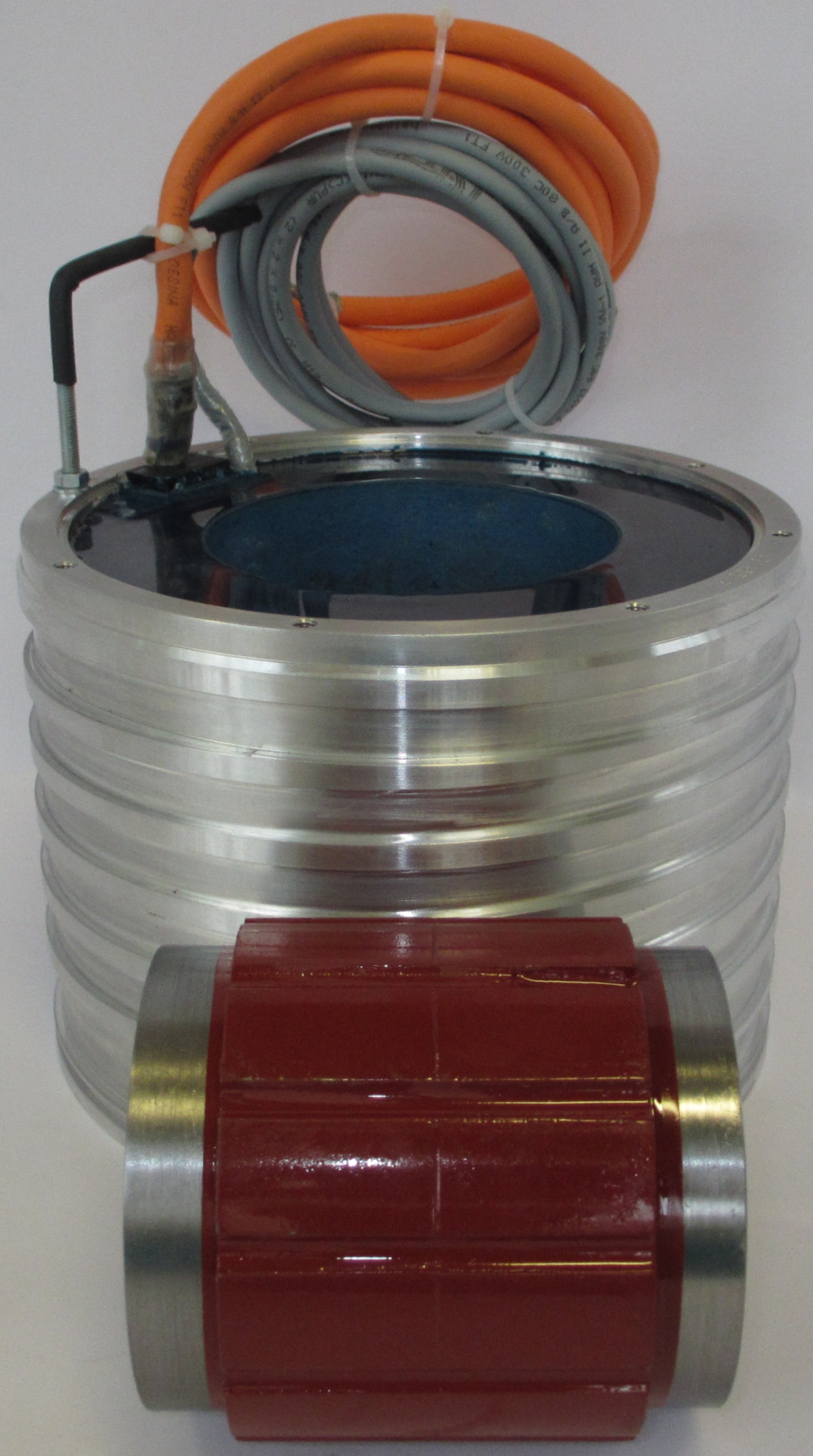

For operation at higher-than-rated speed, we recommend fiber glass encapsulation of the rotor magnets, in addition to the existing glue bonding. See image on the right-hand side. The encapsulation is under tension, thus protecting the rotor magnets against centrifugal forces. Also, the encapsulation protects the motor against vibrations and also against moisture. In addition, the encapsulated rotor is suitable for applications where the motor is immersed in dielectric oil under pressure ( i.e. pressure compensated bath) for example in subsea applications, to keep out salt water.

Another way to protect the motor is not to use glue and polymer material to bond and protect the magnets. Instead, the magnets can be mechanically integrated with the rotor and protected with a stainless steel sleeve (see image in the right-hand side). This type of protection is intended for applications inside a vacuum or when the motor is subjected to ionizing radiation. The protection is also suitable for motors integrated in machines which drive processes with the possibility of infiltration of solvents aggressive to bonding glues despite the protection of the stainless steel sleeve.

Please talk to us about the specifics of your application. We will be pleased to share our experiences with you and propose a hardened torque motor for your application. You can use our contact form to get in touch with us.