Requirements for drive electronics in the aerospace industry

Aerospace motor and drive applications have a number of common, critical requrements :

- High power and torque density

- High efficiency

- Demanding environmental conditions: vibration, shock, temperature, vacuum

- High reliablity and availability, partially ensured by:

two-, three- and four-way redundancy of all electrical and control circutis - Demanding and comprehnsive analysis and test programs

MACCON is involved in projects that involve research and development for applications in these harsh environments. One of the current projects is: TEMA-UAV.

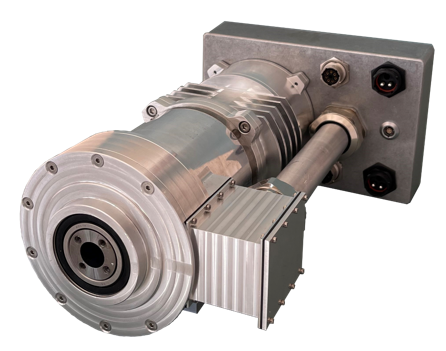

This study is about the Design and Evaluation of Fault-Tolerant Electro-Mechanical Actuators for Flight Controls of Unmanned Aerial Vehicles.

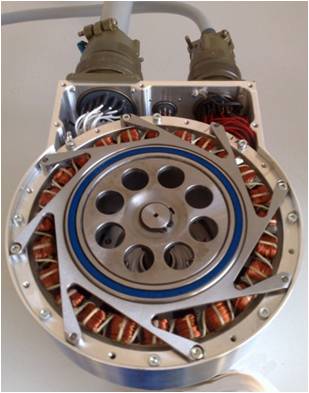

Electro-mechanical actuators (EMAs) are a primary actuation technology for unmanned aerial vehicles (UAVs). Intensive research has been conducted for designing and evaluating fault-tolerant EMAs for flight controls of UAVs to ensure their compliance with new airworthiness requirements for safe operation over civilian zones. The state-of-the-art research involves several fault-tolerant architectures for EMAs based on parallel electric motors or a single motor with internal fault-tolerant features. In this study, a fault-tolerant architecture is introduced, comprised of two serial electric motors driven by two isolated controllers and a health monitoring system. The procedures of developing various fault-tolerant features are discussed with a deep focus on designing health monitoring functions and evaluating their influence on the overall actuator stability and availability. This work has been conducted and evaluated based on operational data for ALAADy: a heavy gyrocopter-type UAV at DLR (German Aerospace Center).